It has been known for about 20 years that special micro-structures simulating the texture of shark skin can lower hull drag by up to 10 per cent. A new process for the production of these coatings on large surfaces has now been developed by researchers in Germany and the process allows coating application, embossing, and partial curing in a single step.

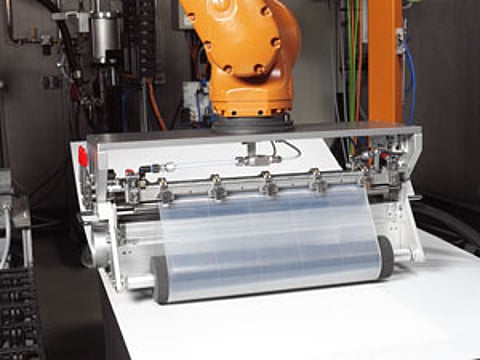

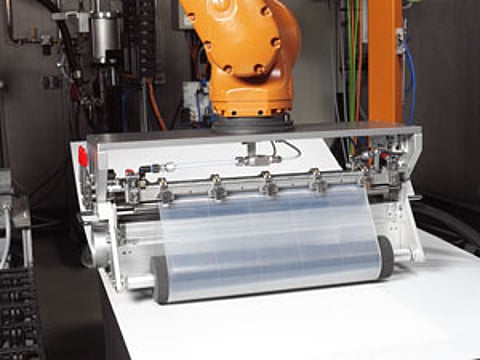

The process involves using a UV-transparent stamp on UV-curable polyurethane lacquer with a solids content close to 100 per cent. After curing in sunlight, the coating will not be runny or tacky.

The coating material is free of volatile organic compounds and contains nano-composites that give the coating the necessary abrasion resistance and weathering stability.

"The results are promising and show the minimum of what is possible in terms of durability. Commercial paint suppliers should be able to outperform that," said Dr Volkmar Stenzel, researcher at Fraunhofer IFAM, Bremen.

Drag measurements carried out in a ship model basin demonstrate a surface-drag reduction of 5.2 percent for a torpedo-shaped specimen.

Further developments of the paint and application process are ongoing including investigations into prevention of biofouling.

Wendy Laursen