Wärtsilä has signed a contract with the German shipowner Jüngerhans, to refit two of its vessels with Wärtsilä Slow Steaming Upgrade Kits to cut fuel costs.

The 1997-built vessels are equipped with seven-cylinder Wärtsilä RTA62U main engines.

"The Wärtsilä Slow Steaming Upgrade Kits will give these ships considerable flexibility for adapting to the prevailing challenging market conditions," Herm Jüngerhans, Managing Director, Jüngerhans, said.

"They offer considerable cost savings when slow steaming the ships, while retaining the capability for full speed whenever necessary."

In response to over-capacity in the market and a desire to cut overall fuel consumption, during recent months charterers have adjusted both their services and the speed of their ships. Slow steaming has become an established way of operating vessels, particularly in the container segment. Slow steaming offers clear benefits for charterers in terms of substantially reduced fuel consumption and considerable savings in overall ship operating costs.

Wärtsilä Slow Steaming Upgrade Kit

For ships powered by Wärtsilä RTA and RT-flex low-speed engines with more than one turbocharger, Wärtsilä introduced its Slow Steaming Upgrade Kit in 2008. The kit enables ship owners and operators to achieve major savings in fuel costs by allowing them to slow steam their ships.

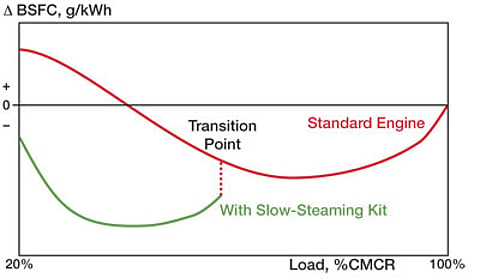

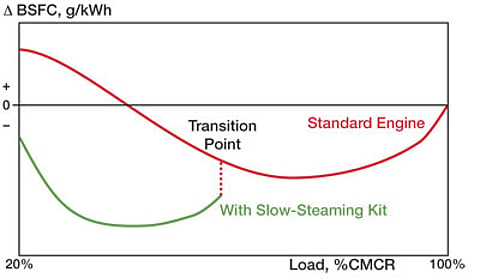

"The Slow Steaming Upgrade Kit both extends the load range of the engine for continuous operation, and significantly reduces BSFC (brake specific fuel consumption) in the low-load range," explained Jürgen Gerdes, Director, Services, Wärtsilä in Switzerland.

The Wärtsilä Slow Steaming Upgrade Kit also helps ship owners, operators and charterers to increase the flexibility of their engines, permitting them to run anywhere from ten percent to 100 percent maximum load without operational restrictions, and to decrease the risk of engine fouling and excessive component temperatures.

The BSFC figures that can be achieved are strongly dependent on the final nitrogen oxide emission balances over the entire load range.

For ships that must comply with the IMO nitrogen oxide emission regulations, the restrictions imposed by the emissions limits will be evaluated in each case and a customized solution package offered.

"Operational flexibility was a major factor in our decision to choose Wärtsilä's solution.We wanted to have a reliable slow steaming solution in order to be attractive in the market and this gives us an advantage over other charterers," added Mr Jüngerhans.

Other orders and first operating results

With the order from Jüngerhans, the total number of ordered upgrade kits has increased to twelve, and Wärtsilä is already able to assess the initial operating results for its Slow Steaming Upgrade Kit.

For an eight-cylinder Wärtsilä RTA62U engine, it was possible to achieve fuel savings of up to 6-10 g/kWh in the optimal load range. On a twelve-cylinder Wärtsilä RT-flex96C engine equipped with three turbochargers, the measured fuel savings of 8-12 g/kWh were slightly higher because the achievable savings are related to the number of turbochargers. Since installation, the vessels have been running successfully and the customers have had the flexibility of choosing whether to slow steam or not.

For further information contact: