Swedish technology company Cetasol has developed a new type of virtual sensor for fuel flow measurement.

The CetaFuel sensor can accurately measure properties without requiring physical sensors. Cetafuel said this technology can replace traditional and expensive fuel flow meters, making fuel monitoring more accessible and affordable, especially for older vessels with mechanical engines that do not have access to reliable fuel reading technology.

Measuring the fuel consumption of a vessel is an important first step to improving operations, reducing costs, and lowering emissions. Cetasol said it has been estimated that 25 per cent of total marine engines do not have built-in fuel sensors by manufacturers. These engines, also known as mechanical engines, need external flow meters (usually two per engine for inlet and outlet fuel flow) to measure the fuel consumption of the engines. However, traditional physical flow meters used to measure fuel consumption can be expensive, challenging to install, and require frequent calibration which is a point of concern regarding fuel blockage. Coriolis flow meters offer greater accuracy and do not clog the fuel flow, but they are more expensive and can be more complex to install.

CetaFuel is a virtual sensor for fuel reading without requiring extensive and expensive installations. Cetasol said this attribute makes the solution more affordable compared to other flowmeters that can be challenging to install. The virtual sensor's measurement is created from a model of the physical sensor and can replace a physical sensor. This sensor can be used as a "digital twin" to monitor system health and drifts.

The company added that CetaFuel offers a sustainable solution that maintains accuracy and removes installation complexities and concerns about after installation maintenance. The sensor requires minimal maintenance and calibration and is not prone to drift over time.

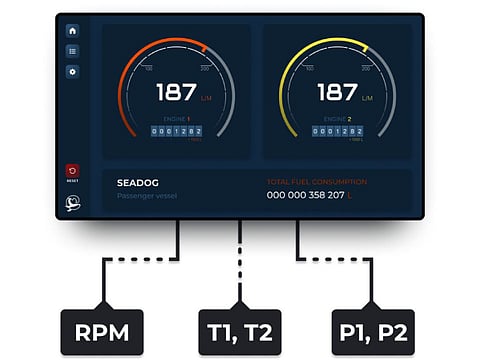

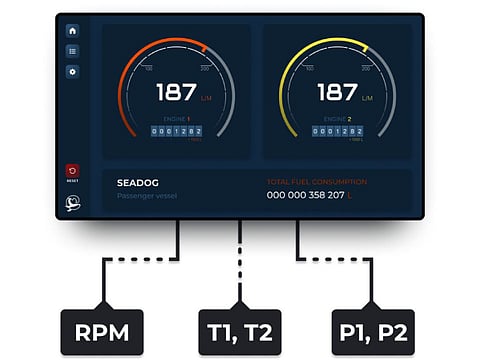

To create the CetaFuel virtual sensor, Cetasol adapted its powertrain knowledge to the development of a similar solution as an internal engine control unit. The solution is an external calculating module running on Cetasol's main computing unit. With sensors available – such as those for measuring rpm, pressure, and temperatures – the model was recalibrated. The model can be flexible to any available sensors and adapts to every vessel, as a result of calibrations.

While developing the product, the first step was to create a pool of reference engines to find an engine that matches the customer's vessel in terms of specification and setup. To adapt the sensor for each vessel, Cetasol modeled the fuel consumption according to the available parameters, using the company's library pool to pick the best match or corresponding fuel models. With the use of the target model, the fuel consumption is predicted and then corrected with the measurements from the customer.

To demonstrate the effectiveness of CetaFuel, Cetasol tested the virtual sensor on three vessels located in the Nordic region: the passenger ferries Brim (Norway; pictured) and Burö (Sweden) and a high-speed Ro-Pax ferry operated by Danish transport company Molslinjen. The vessels varied in size, engine make, and routes. The largest vessel is 110 metres long with a gross tonnage of 10,500 and a total power of 36,000 kW.

From data and analyses, Cetasol is able to provide accuracy measurement and compare it for different engine brands and sizes. With access to some basic engine measurements, e.g. rpm, pressures and temperatures, the accuracy can be up to 99 per cent. Cetasol offers a simple sensor installation to provide high accuracy measurements. For the cases where only rpm is available, the company recommends the installation of one additional signal, which is easy to install.

Cetasol said it should be noted that mass flow meters offer the same accuracy level but need to be calibrated and add a risk of blocking fuel flow. CetaFuel can be installed at a fraction of the cost of a physical sensor and require no additional sensor installation, while still having the same degree of accuracy as a physical sensor. The best results are shown when two or more measurements are available from the engine.

Cetasol created a pool of reference engines to develop the CetaFuel virtual sensor and modeled the fuel according to the available parameters. With the Cetasol library, they can select the best match or corresponding fuel models. The virtual sensor's fuel consumption is predicted and then corrected with the measurements from the customer and provides fuel reading with high (i.e., 96 to 99 per cent) accuracy. Cetafuel uses other available measurements from the engine to create a digital twin of the engine, and the digital twin model will be used for energy predictions.